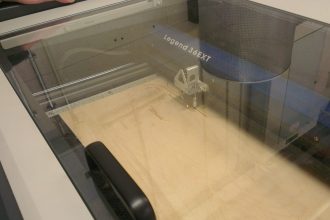

The steering wheel shape took inspiration from a product made by major FSAE manufacturer, Formula Seven. Using their dimensions and rough estimates of sizes for the chosen display components, the first prototype was laser cut from plywood. This prototype was mainly used to study the driver ergonomics and determine that the wheel was comfortable to hold.

Plasticine was used to quickly mold some example hand grips, instantly making the mock-up wheel more comfortable to hold. We altered thickness, radii and certain features such as thumb impressions to create a wheel that suited the majority of the team. Inspired by other formula student teams, we hoped to 3D scan these grips to create cad models. With some modification these could of been AM (additive manufacture) printed to create identical parts out of ABS plastic. Unfortuantely unable to source a 3D scanner by our target date, we instead created basic grips within Solidworks using measurements from the plasticine models.

After determining the idea wheel width and hand hold dimensions, revision 2 was created. This also had the correct component dimensions, allowing us to partially assemble the wheel and check critical clearances. The finalised hand grips were temporarily attached. As predicted, the steering was put through it’s paces by all the team ( most making the necessary car noises).

Next… Steering Wheel – FEA Load Testing