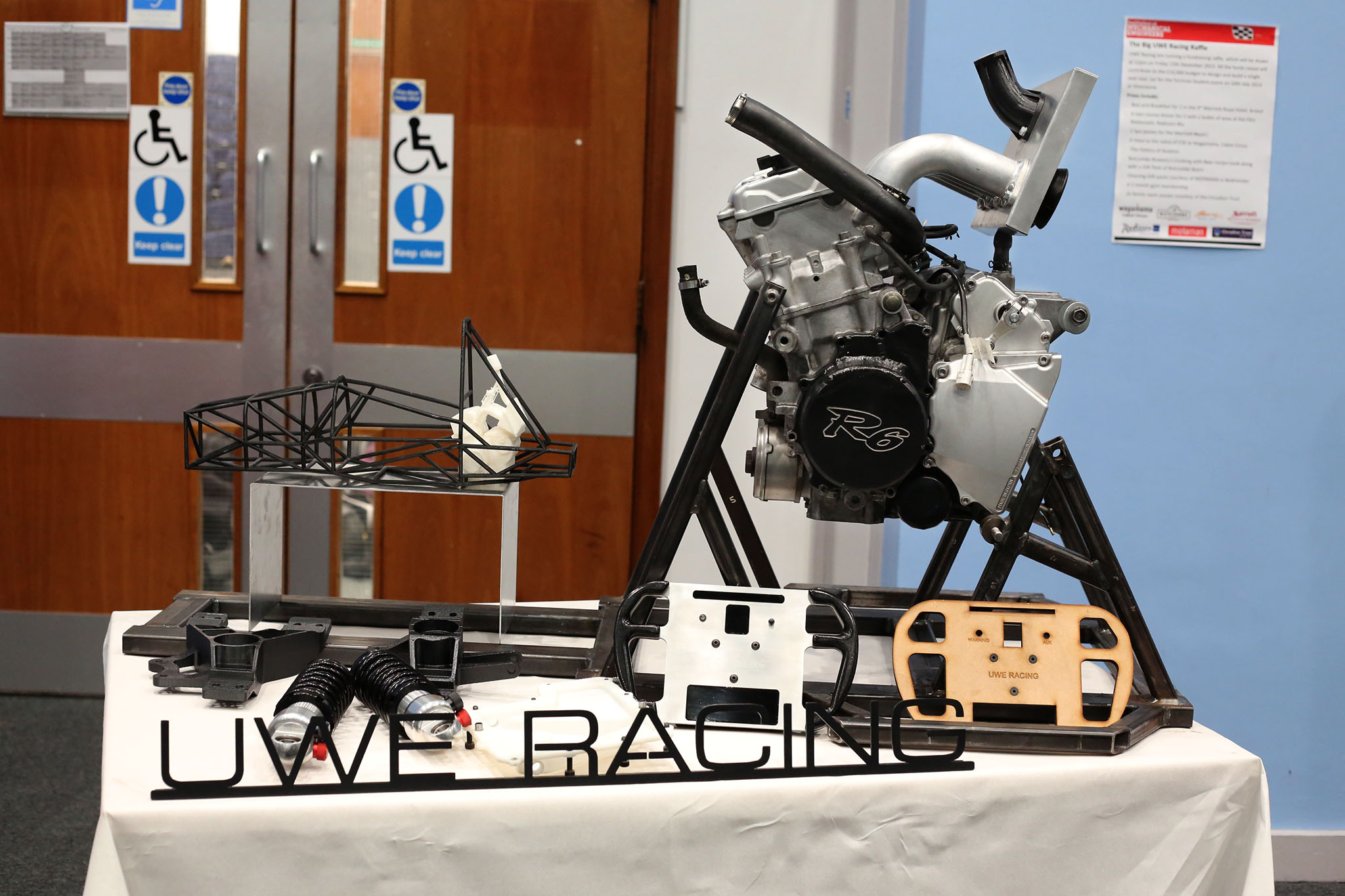

This is a rather late post considering that I carried out the work over the summer period. During the Formula Student competition in July, we entered our first Class 1 car. Through a tremendous amount effort, determination and many late nights we took a near completed, but not yet run car to the event. There were many parts of the car that still required assembly, some that needed to be altered to meet the strict scrutineering and nearly all were untested…

One of the major systems that did not get any much needed testing before the event were the brakes, this proved to be our Achilles heel. During the final scrutineering event which was the brake test, even after multiple attempts we still failed to lock up all four wheels. There was a lack of pressure in the braking system, which was due to flexibility in the pedalbox. During the event we had made numerous attempts to strengthen the assembly using whatever scraps of metal we could find and weld on. Unfortunately this was not enough and we ended up damaging the pedalbox in the final brake test.

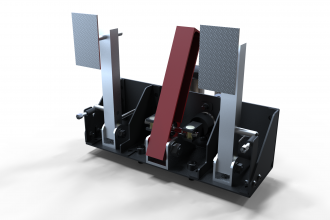

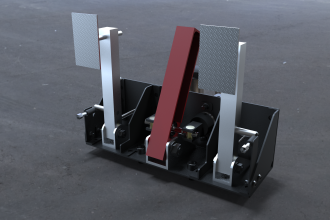

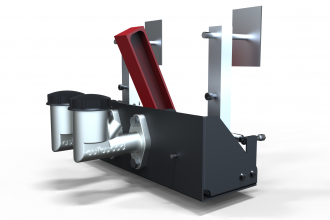

During the summer after the event, I modified the existing pedalbox and improved the way in which the cables were actuated. The box was laser cut out of 3mm mild steel, this eliminated any possible flexibility, even under the test load of 2000N. Modifications were also made to allow for easier assembly and adjustment of the throttle and clutch cables. When installed back in the car, there was a noticeable difference in the stiffness of the brake pedal, all four wheels locked up with minimal brake pedal travel.

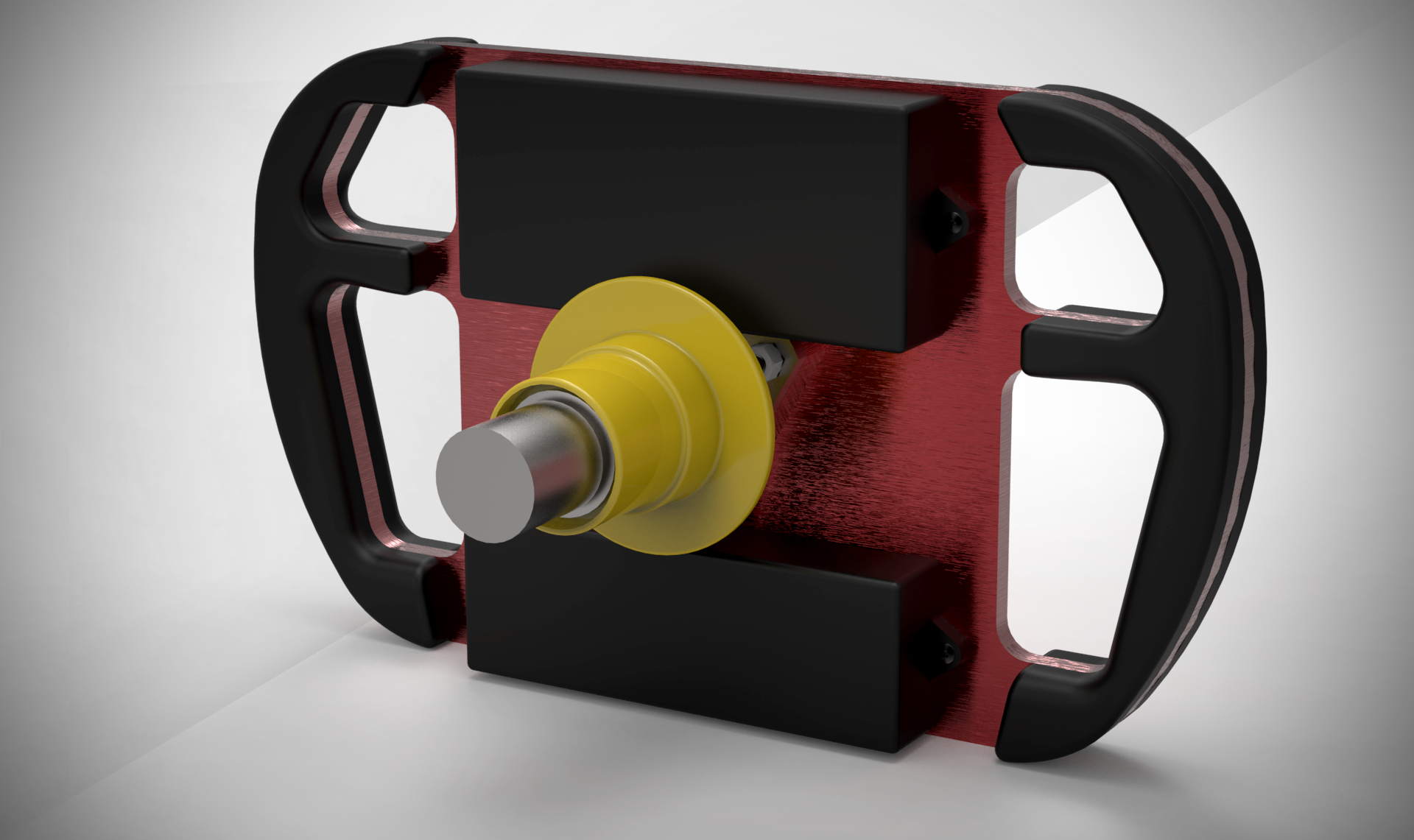

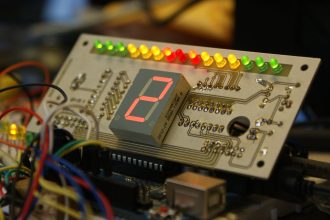

I have made the files for both the electronic steering wheel and the pedalbox available on Grabcad. I hope they will be of use to Formula Student teams looking for inspiration or hobbyists looking for a fun project.